Ultrasonic swing screen is a new type of low-speed screening equipment designed to achieve fine screening and impurity removal of materials. The ultrasonic swing screen simulates the manual screening action and process of humans, performing three-dimensional circular motion and cleverly combining the screening material (planar circular motion) and the throwing motion (upward throwing motion). It has both circular motion and upward throwing arc motion, so the swing screen has the characteristics of high screening accuracy, high efficiency, large output, and long screen life.

Ultrasonic swing screen is applied to various fine powders and ultrafine metal powders, and is more suitable for materials that are difficult to handle with ordinary circular vibrating screens. Ultrasonic swing screen can meet the physical properties of different materials and customer screening requirements by adjusting the independent and adjustable speed, eccentricity, and radial force, changing the time and movement path of materials on the screen surface to achieve ideal screening effect.

High screening efficiency, mature and stable design, any powder or irregularly shaped particles can be screened.

The standardized circular building block assembly structure of the whole machine makes installation and disassembly easier.

The mesh holes on the screen are not easily clogged, lightweight powder is not easy to fly, and can be screened up to 500 mesh or 0.028mm.

Simulating human manual screening actions and processes, the screening accuracy can reach about 90-95%.Standardize the design of the grid structure, extend the service life of the mesh, and replace the mesh quickly, taking only 10-20 minutes.

The whole machine is designed with silent operation, with a noise level of only 45dba, fully enclosed operation, no powder flying, and no liquid leakage.Soft rock screening will not damage the original particle structure of the material.

The screening process is less prone to static electricity and is more suitable for screening materials that are flammable, explosive, and prone to static electricity.Each layer has an effective screening area of 0.28-6.4 square meters, which can be recycled up to 1-5 layers.

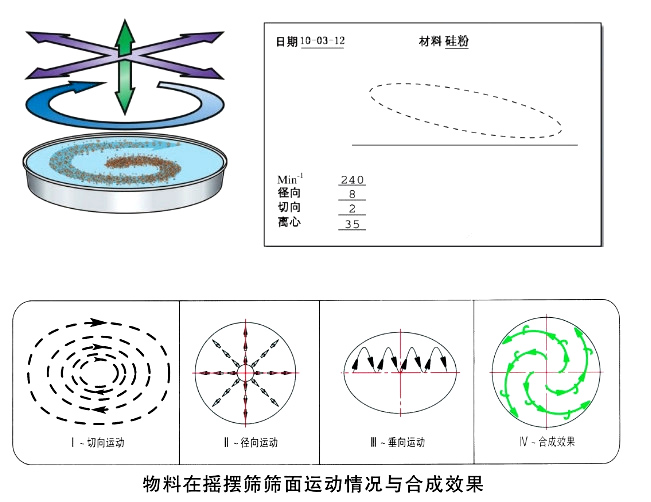

The basic rotary motion of ultrasonic swing screen is similar to manual screening. It uses a 380V motor to drive the oscillating body to generate a three-dimensional swinging effect. The three-dimensional swinging causes the material to exhibit an arc-shaped involute swinging motion trajectory on the screen, and the material achieves the expected screening and impurity removal effect during the swinging motion. The motion trajectory of the swing screen itself is elliptical, and the dwell time of each product can be adjusted by adjusting the longitudinal and tangential angles on the oscillating body to change the motion trajectory of the material on the mesh surface. The eccentricity can be adjusted from 25 to 40mm, and the low-speed V-belt drive can be adjusted freely from 120 to 360rpm.

The material input into the swing screen is uniformly dispersed on the screen surface from the center to the outer edge in the form of spiral motion propagating axially, and particles close to the size of the screen are successfully separated accordingly; The larger particles that do not pass through the sieve are transported to the outlet of the upper sieve surface and discharged, and the materials that pass through the sieve holes are dropped to the lower sieve surface for screening.

Model | Effective screening diameter | Effective screening area | Screen angle | Number of layers | Power |

YBS-600 | Φ600 | 0.21 | 0-10 | 1-5 | 0.75 |

YBS-1000 | Φ1000 | 0.66 | 0-10 | 1-5 | 1.1 |

YBS-1200 | Φ1200 | 0.98 | 0-10 | 1-5 | 2.2 |

YBS-1600 | Φ1600 | 1.81 | 0-10 | 1-5 | 4 |

YBS-2000 | Φ2000 | 2.8 | 0-10 | 1-5 | 5.5 |

Ultrasonic swing screens are widely used in industries such as chemistry, chemical engineering, food and fragrance, plastics and synthetic resins, mining, medicine, wood and plywood, wood, building materials, metallurgy, cement, casting, abrasives, papermaking rubber, feed, fertilizer, sugar and salt industry, recycling industry, etc. for dry wet vibration screening of particle and powder related industries, as well as liquid-solid separation and wastewater filtration and recovery.

cement

cement chemical fertilizer

chemical fertilizer Traditional Chinese Medicine Powder

Traditional Chinese Medicine Powder Traditional Chinese Medicine Granules

Traditional Chinese Medicine Granules Traditional Chinese Medicine Liquid

Traditional Chinese Medicine Liquid MessageWe provide you with customized Screening Solution

MessageWe provide you with customized Screening SolutionIf you don't know how to choose, please call us or leave a message online. We will be happy to serve you!

Rich Production Experience

Rich Production Experience

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Complete production line design

Complete production line design

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

High-Quality After-Sales Service

High-Quality After-Sales Service

Our company has a well-established after-sales service management system. Customers facing product issues can receive immediate assistance 24/7 via our dedicated support hotline.

Renowned in over 100 countries and regions worldwide, our premium products and services have earned the trust of leading global brands and Fortune 500 enterprises.