The square swing screen is an efficient screening equipment developed and designed to meet the needs of users with high output and precision. The square swing screen is suitable for precise screening of particles and powder materials with a moisture content below 200 mesh, which are not easily agglomerated.

The stainless steel square swing screen is made of 304 stainless steel material and is used for production work in industries with GMP requirements or anti-corrosion requirements.

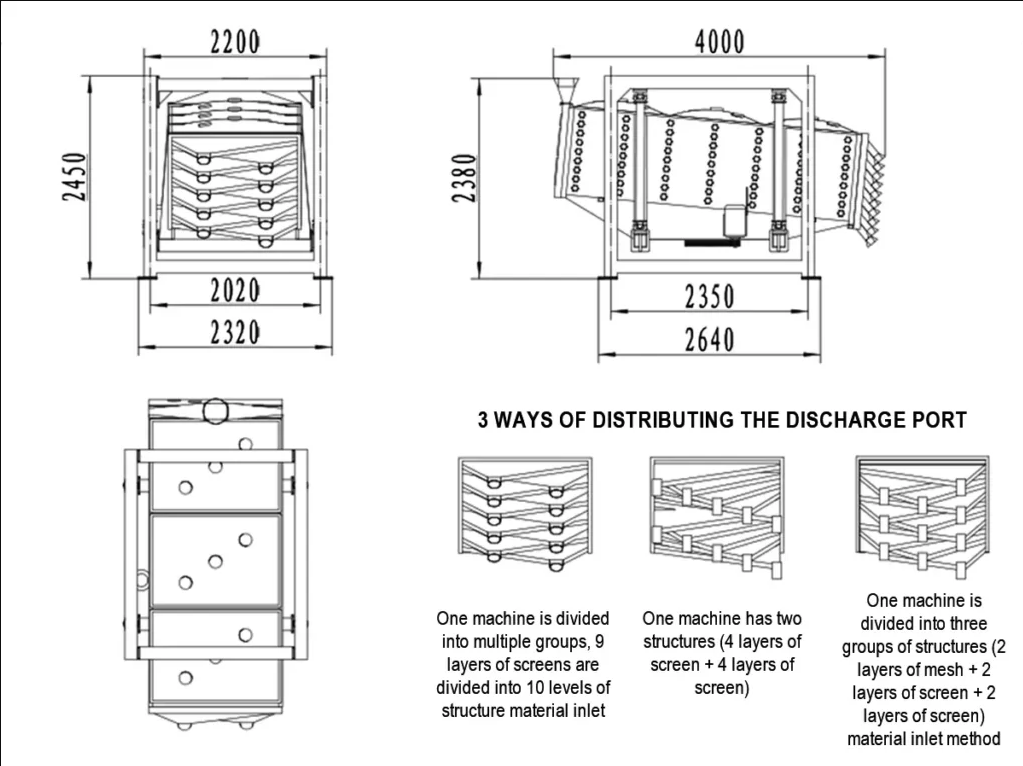

Unique multi-layer grading design

Unique multi-layer grading design, with one unit equivalent to multiple units, doubling production capacity;

Flexible screening

Flexible screening, long material running trajectory, high screening accuracy, and easy assembly line operation;

Good self-cleaning effect

Good self-cleaning effect, each layer of the screen has high elasticity silicone balls, which are not easy to block the net;

The screen has a high utilization rate

The screen has a high utilization rate, quick replacement, long service life, and can be repaired if damaged;

Fully enclosed without dust

Fully enclosed without dust, low noise, environmentally friendly and energy-saving;

Made of 304 material

Made of 304 material, in compliance with GMP standards, and possessing CE certification.

After the screening machine is started, the shaking body of the screening machine, that is, the screening box, moves back and forth under the action of inertia. The screening box drives the screening surface to shake periodically, so that the material on the screening surface moves in a directional jumping motion together with the screening box. During this process, the material smaller than the aperture of the screening surface falls to the lower layer through the screening hole, becoming the undersized material. The material larger than the aperture of the screening surface is discharged from the discharge port after continuous rolling and jumping motion, thus completing the screening work.

Equipment model (Single feed) | Effective screening area(㎡) | Power(KW) | Screen surface inclination(°) | Number of layers | Cyclotron frequency(r/min) | Screening box travel |

XFYBS1030 | 3 | 3 | 5-8 | 1-5 | 180-260 | 25-60 |

XFYBS1036 | 3.6 | |||||

XFYBS1230 | 3.6 | 4 | ||||

XFYBS1236 | 4.32 | |||||

XFYBS1530 | 4.5 | 5.5 | ||||

XFYBS1536 | 5.4 | |||||

XFYBS1830 | 5.4 | 7.5 | ||||

XFYBS1836 | 6.48 | |||||

XFYBS2030 | 6 | |||||

XFYBS2036 | 7.2 | |||||

Equipment model (dual feed) | Effective screening area(㎡) | Power(KW) | Screen surface inclination(°) | Number of layers | Cyclotron frequency(r/min) | Screening box travel |

XFYBS1536-6S | 5.4 | 5.5 | 5-8 | 6 | 180-260 | 25-60 |

XFYBS1536-8S | 8 | |||||

XFYBS1836-6S | 6.48 | 7.5 | 6 | |||

XFYBS1836-8S | 8 | |||||

XFYBS1836-10S | 10 | |||||

XFYBS2036-6S | 7.2 | 6 | ||||

XFYBS2036-8S | 8 | |||||

XFYBS2036-10S | 11 | 10 |

Scope of application: Building materials, mineral processing, metallurgy, chemical industry, abrasives, food and other industries

Applicable materials: dry powder mortar, machine-made sand, natural sand, quartz sand, perlite, dolomite, calcite, potassium feldspar and other various stone powders and mineral powders; Classification of industries such as metallurgy, metal powder, mineral powder, food, sugar, salt, abrasives, and feed

Industrial salt

Industrial salt Metal powder

Metal powder Quartz sand

Quartz sand Perlite

Perlite machine-made sand

machine-made sand mineral powder

mineral powder White sugar

White sugar food additives

food additives salt

salt MessageWe provide you with customized Screening Solution

MessageWe provide you with customized Screening SolutionIf you don't know how to choose, please call us or leave a message online. We will be happy to serve you!

Rich Production Experience

Rich Production Experience

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Complete production line design

Complete production line design

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

High-Quality After-Sales Service

High-Quality After-Sales Service

Our company has a well-established after-sales service management system. Customers facing product issues can receive immediate assistance 24/7 via our dedicated support hotline.

Renowned in over 100 countries and regions worldwide, our premium products and services have earned the trust of leading global brands and Fortune 500 enterprises.