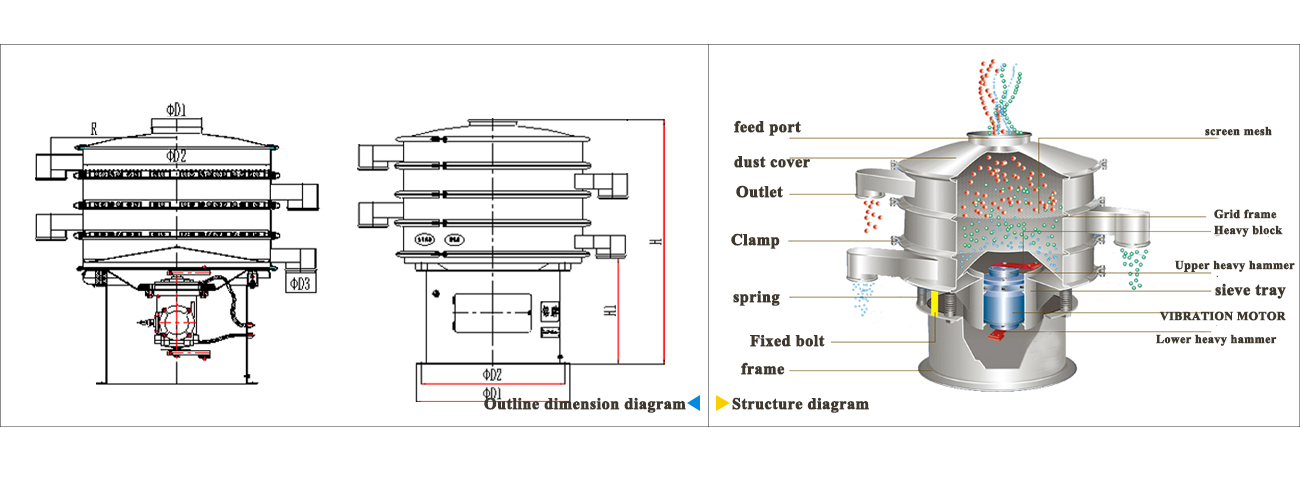

Rotary vibrating screen</a> uses a vertical vibration motor as the exciter. The upper and lower ends of the vibration motor are equipped with eccentric weights, which convert the rotational motion of the vibration motor into horizontal, vertical, and tilted three-dimensional motion, and then transfer this motion to screen surface. Adjusting the phase angles of the upper and lower ends can change the movement trajectory of the material on the screen surface.

Convenient operation, reducing manual labor intensity;

The convenience of replacing the screen mesh and the cleanliness of the mesh rack installation;

Adopting different design processes and quality inspection standards, such as welding and polishing processes;

Select accessories of different materials according to the customer's requirements。

The explosion-proof vibrating screen is excited by a vertical vibration motor. Eccentric heavy hammers are installed at the upper and lower ends of the vibration motor to convert its rotational motion into horizontal, vertical, and inclined three-dimensional motion, which is then transmitted to the screen surface. Adjusting the phase angle between the upper and lower ends can change the motion trajectory of the material on the screen surface.

Table of Appearance and Dimensional Parameters:

Model | φD1(mm) | φD2(mm) | φD3(mm) | R(mm) | H(mm) | H1(mm) | φ1(mm) | φ2(mm) | Foot hole(mm) |

XFFB-600 | 246 | 560 | 100 | 427 | 988 | 390 | 636 | 586 | 3-φ12.5 |

XFFB-800 | 246 | 760 | 150 | 560 | 1200 | 480 | 680 | 630 | 6-φ12.5 |

XFFB-1000 | 246 | 930 | 150 | 645 | 1280 | 556 | 800 | 750 | 6-φ12.5 |

XFFB-1200 | 400 | 1130 | 180 | 747 | 1400 | 560 | 980 | 920 | 6-φ12.5 |

XFFB-1500 | 400 | 1430 | 180 | 900 | 1460 | 580 | 1190 | 1120 | 6-φ12.5 |

Technical parameter table:

Model | Nominal diameter of sieve surface(mm) | Screen surface area(m2) | Mesh size (mesh/inch) | Number of layers(s) | power(kW) | Explosion proof mark of motor | Electromotor |

XFFB-600 | 560 | 0.23 | 2~500 | 1~5 | 0.25 | Ex d IIB T4 Gb或Ex tb IIIC T130°C Db | YBZL-1005-4 |

XFFB-800 | 760 | 0.42 | 0.37 | YBZL-1208-4 | |||

XFFB-1000 | 930 | 0.64 | 1.1 | YBZL-1420-4 | |||

XFFB-1200 | 1130 | 0.95 | 1.1 | ||||

XFFB-1500 | 1430 | 1.61 | 1.5 | YBZL-1630-4 |

Lithium iron phosphate, ternary materials, graphite, polysilicon, monocrystalline silicon, sugar powder, starch, salt, Rice noodles, milk powder, soybean milk, egg powder, soy sauce, fruit juice, tea, drinks, dairy products, candy, snacks, quick-frozen food, condiments, protein, food additives, industrial drugs, traditional Chinese medicine powder, pellets, pellets, resins, coatings, cosmetics, paint, aluminum powder, lead powder, copper powder, ore, alloy powder, welding rod powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, grinding powder, refractory materials, kaolin, lime, aluminum oxide, heavy calcium carbonate, quartz sand, waste oil, waste water, dye Whole wastewater, papermaking, additives, activated carbon, etc.

MessageWe provide you with customized Screening Solution

MessageWe provide you with customized Screening SolutionIf you don't know how to choose, please call us or leave a message online. We will be happy to serve you!

Rich Production Experience

Rich Production Experience

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Complete production line design

Complete production line design

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

High-Quality After-Sales Service

High-Quality After-Sales Service

Our company has a well-established after-sales service management system. Customers facing product issues can receive immediate assistance 24/7 via our dedicated support hotline.

Renowned in over 100 countries and regions worldwide, our premium products and services have earned the trust of leading global brands and Fortune 500 enterprises.