As a kind of high-efficiency screening equipment, swinging screen plays an important role in industrial production. Its structure design is precise, mainly composed of a special screen box, a powerful driving device and a stable support component. The unique design of the screen box enables it to produce complex and precise controllable swing movement, in the chemical industry, food, medicine, mining and other fields, for all kinds of materials with different nature, swing screen can rely on excellent performance, the material is accurately classified according to the particle size, high screening efficiency, precision, greatly improving the efficiency of the material screening link in the production process. It is one of the key equipment to ensure efficient and stable production in various industries.

Effectively imitating the manual screening action and process, with a screening accuracy of up to 90-95%;

Made of 304 stainless steel material, it is more wear-resistant and has a longer service life;

Multiple cleaning devices can be added (such as bouncing balls to clean the mesh surface, ultrasonic technology to clean the mesh surface, etc.), which can effectively solve the problem of screen blockage, ensure the continuity of screening, have a fully enclosed structure, and reduce environmental pollution;

Fully enclosed structure, reducing environmental pollution, with noise levels as low as 75dBa;

Multiple cleaning methods, including bouncing ball cleaning, ultrasonic cleaning, and brush cleaning, ensure that the screen mesh is not blocked or deformed, resulting in higher screening efficiency;

Free design can be provided according to user needs.

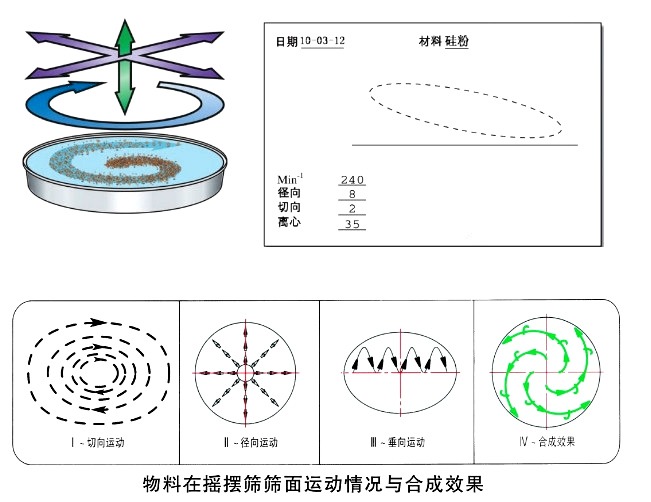

The basic rotary motion of stainless steel swing screen imitates the manual screening action. The eccentricity can be adjusted from 25 to 40mm, and the oscillation frequency can be adjusted from 120 to 360rpm. When the power is turned on, the sieve box is driven by the vibration device to make approximate circular motion. At this time, the sieve box drives the entire sieve surface to make periodic motion. The material on the sieve surface moves in a directional jumping motion along with the sieve box on the sieve. During this process, the material smaller than the sieve aperture falls to the lower layer of the sieve and is discharged from the lower discharge port, the material larger than the sieve aperture is discharged from the upper discharge port, and the middle layer is discharged from the middle discharge port to complete the entire screening work.

Model | Effective screening diameter | Effective screening area | Screen angle | Number of layers | Power |

YBS-600 | Φ600 | 0.21 | 0-10 | 1-5 | 0.75 |

YBS-1000 | Φ1000 | 0.66 | 0-10 | 1-5 | 1.1 |

YBS-1200 | Φ1200 | 0.98 | 0-10 | 1-5 | 2.2 |

YBS-1600 | Φ1600 | 1.81 | 0-10 | 1-5 | 4 |

YBS-2000 | Φ2000 | 2.8 | 0-10 | 1-5 | 5.5 |

YBS-2400 | Φ2400 | 4.15 | 0-10 | 1-4 | 5.5 |

YBS-2600 | Φ2600 | 5.31 | 0-10 | 1-4 | 5.5 |

YBS-3200 | Φ3200 | 7.5 | 0-10 | 1-4 | 11 |

Application scope: Food industry, pharmaceutical industry, chemical industry, etc

Application materials: citric acid, milk powder, starch, sugar, vitamins, spices, tea, feed, plastics, rubber, fertilizers, sugar salt industry, renewable resources EPS、PVI 、PVC、 Resin, etc.

MessageWe provide you with customized Screening Solution

MessageWe provide you with customized Screening SolutionIf you don't know how to choose, please call us or leave a message online. We will be happy to serve you!

Rich Production Experience

Rich Production Experience

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Complete production line design

Complete production line design

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

High-Quality After-Sales Service

High-Quality After-Sales Service

Our company has a well-established after-sales service management system. Customers facing product issues can receive immediate assistance 24/7 via our dedicated support hotline.

Renowned in over 100 countries and regions worldwide, our premium products and services have earned the trust of leading global brands and Fortune 500 enterprises.