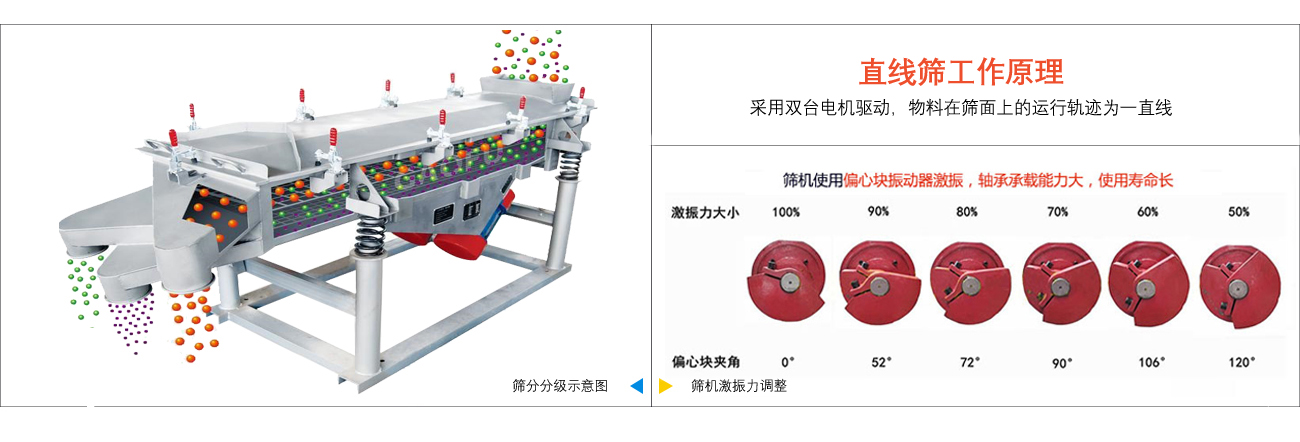

The large linear vibrating screen uses high-quality vibration motors as the vibration source. This screen machine is equipped with two vibration motors. During operation, the eccentric blocks of the two motors rotate in opposite directions. The combined force of the two motors in the horizontal direction is zero, and a combined force is formed perpendicular to the motor axis direction. The motor axis forms a certain angle with the screen plate, and the combined force causes the material to be thrown up on the screen while moving forward. The material is uniformly fed into the feeding port of the screening machine through the feeder, and several types of products and unqualified oversize and undersize materials are produced through multiple layers of different aperture screens, which are discharged from their respective outlets.

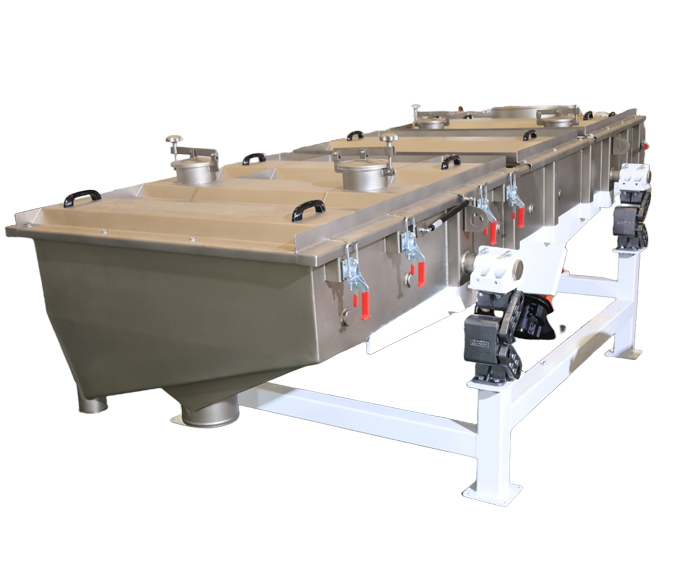

Low energy consumption, low noise, and long service life of the screen mesh.

High screening accuracy, large processing capacity, and simple structure.

The process of replacing the screen mesh is simple and the equipment operation is convenient.

Reasonably matching the sieve can achieve the simultaneous screening of multiple products of different specifications.

Fully enclosed structure, automatic discharge, easy maintenance, more suitable for assembly line operations, good sealing, and minimal dust spillage.

All incoming materials are automatically discharged and there are no stored materials inside the machine.Automatic net cleaning device, not easy to block the net.

When the linear sieve is working, the two motors rotate synchronously in reverse, causing the exciter to generate reverse excitation force, forcing the sieve box to drive the screen mesh to move longitudinally, causing the material on it to be periodically thrown forward by the excitation force, thus completing the material screening operation. When two vibration motors rotate synchronously and in reverse, the excitation force generated by their eccentric blocks cancels each other out in the direction parallel to the motor axis, and forms a resultant force in the direction perpendicular to the motor axis. Therefore, the motion trajectory of the screening machine is a straight line. The two motor shafts have an inclination angle in the vertical direction relative to the screen surface. Under the combined force of excitation force and material self gravity, the material is thrown up and jumps or moves forward in a straight line on the screen surface, thereby achieving the purpose of screening and grading the material.

Model | Nominal size(mm) | Material particle size(mm) | Slope inclination angle(°) | amplitude(mm) | Number of layers(s) | power(kw) |

XFZ520 | 500×2000 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2×(0.4~0.75) |

XFZ525 | 500×2500 | 2×(0.4~0.75) | ||||

XFZ530 | 500×3000 | 2×(0.75~1.1) | ||||

XFZ535 | 500×3500 | 2×(0.75~1.1) | ||||

XFZ1020 | 1000×2000 | 2×(0.75~1.5) | ||||

XFZ1025 | 1000×2500 | 2×(1.1~1.5) | ||||

XFZ1030 | 1000×3000 | 2×(1.5~1.8) | ||||

XFZ1035 | 1000×3500 | 2×(1.5~2.2) | ||||

XFZ1040 | 1000×4000 | 2×(1.5~2.2) | ||||

XFZ1225 | 1200×2500 | 2×(1.5~2.2) | ||||

XFZ1230 | 1200×3000 | 2×(1.8~3) | ||||

XFZ1235 | 1200×3500 | 2×(1.8~3) | ||||

XFZ1530 | 1500×3000 | 2×(2.2~3) | ||||

XFZ1535 | 1500×3500 | 2×(2.2~3) | ||||

XFZ1540 | 1500×4000 | 2×(2.2~4) |

This product is widely used for screening dry powder or granular materials in industries such as chemical, food, plastic, pharmaceutical, metallurgical, glass, building materials, grain, fertilizer, abrasive, ceramics, etc. Screening of various dry powder or granular materials with a particle size of 0.074-5mm, a moisture content of less than 7%, and no viscosity. The feeding particle size shall not exceed 10mm.

MessageWe provide you with customized Screening Solution

MessageWe provide you with customized Screening SolutionIf you don't know how to choose, please call us or leave a message online. We will be happy to serve you!

Rich Production Experience

Rich Production Experience

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Complete production line design

Complete production line design

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

High-Quality After-Sales Service

High-Quality After-Sales Service

Our company has a well-established after-sales service management system. Customers facing product issues can receive immediate assistance 24/7 via our dedicated support hotline.

Renowned in over 100 countries and regions worldwide, our premium products and services have earned the trust of leading global brands and Fortune 500 enterprises.