Rotary vibrating screen is a screening equipment that integrates impurity removal, grading, and filtration. It can easily screen dry, wet, fine, rough, and specific gravity powders and particles with a mesh size of 0-500. It can also filter slurry materials with a mesh size of 0-600, and can be used in single or multiple layers simultaneously, up to 5 layers.

Can meet the screening needs of various powders and particles, as well as liquid filtration needs, with screening fine to 500 mesh or 0.028mm, and liquid materials can be filtered to 5 microns.

Under each layer of the screen, there is a bouncing net cleaning device installed. By continuously hitting the screen, the material can be screened smoothly and the problem of material blockage can be effectively avoided.

Impurities and coarse materials are automatically discharged and can be operated continuously, with a production capacity of up to 5 tons/hour.

1-5 layers of multi-layer screening can obtain 2-6 different specifications of finished products.

Fully sealed structure, no powder overflow, no liquid overflow.

The discharge port can rotate 360 °, and replacing the screen only takes 3-5 minutes.

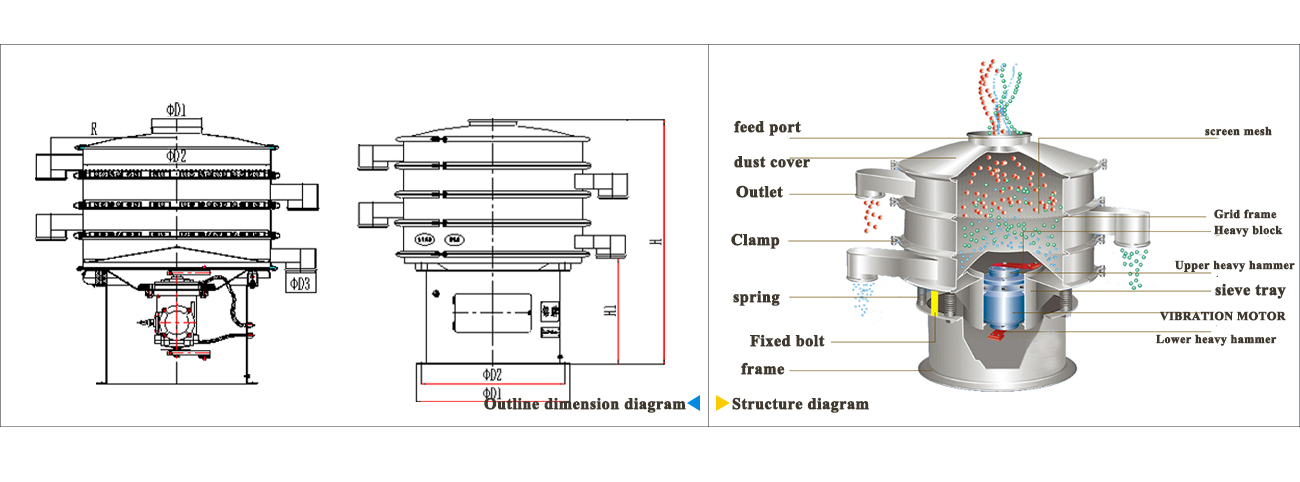

The rotary vibrating screen uses a vertical vibration motor as the excitation source. The rotating motion is converted into horizontal, vertical, and inclined three-dimensional motion through eccentric heavy hammers at the upper and lower ends of the vibration motor, and transmitted to the screen surface of the rotary vibrating screen. The material enters the equipment through the inlet. According to different screening requirements, the material passes through 1-5 layers of screens with different mesh sizes. During this process, the cleaning device located under each layer of screen continuously impacts the screen, allowing the material to be screened smoothly and effectively avoiding the problem of material blockage. The material close to the screen aperture passes through the screen, which is the undersized material. The material larger than the screen aperture is discharged from the outlet of that layer, which is the undersized material. The purpose of completing filtering or filtering.

Equipment parameters:

Model | A(mm) | B(mm) | C(mm) | D(mm) | E(mm) | F(mm) | H(mm) | I(mm) |

XF-600 | 530 | 430 | 246 | 600 | 100 | 70 | 391 | 415 |

XF-800 | 680 | 580 | 246 | 800 | 125 | 80 | 514 | 430 |

XF-1000 | 800 | 700 | 246 | 1000 | 150 | 95 | 615 | 430 |

XF-1200 | 975 | 855 | 400 | 1200 | 180 | 100 | 717 | 550 |

XF-1500 | 1190 | 1050 | 400 | 1500 | 180 | 116 | 866 | 545 |

Table of Appearance and Dimensional Parameters:

Model | Sieving diameter(mm) | Screening area(m²) | Mesh size (mesh/inch) | Number of layers (s) |

XF-600 | φ560 | 0.23 | 2-500 | 1-5 |

XF-800 | φ760 | 0.42 | 1-5 | |

XF-1000 | φ930 | 0.64 | 1-5 | |

XF-1200 | φ1130 | 0.95 | 1-5 | |

| XF-1500 | φ1430 | 1.61 | 1-5 |

Chemical industry: resins, coatings, industrial drugs, pigments, paints, traditional Chinese medicine powders, etc.

Food industry: sugar powder, starch, salt, Rice noodles, milk powder, soybean milk, egg powder, soy sauce, fruit juice, etc.

Metal and metallurgical mining: aluminum powder, lead powder, copper powder, ore, alloy powder, welding rod powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, grinding powder, refractory materials, kaolin, lime, alumina, heavy calcium carbonate, quartz sand, etc.

Pollution treatment: waste oil, wastewater, dyeing and finishing wastewater, additives, activated carbon, etc.

Comparison of material production capacity and models:

Raw material | Proportion | Mesh | Method | Production | Model |

Wheat starch | 1 | 250Mesh | wet | 3200 IT | XF-1200-1S |

flour | 0.6 | 24Mesh | dried | 1500㎏ | XF-1000-1S |

soy sauce | 1 | 100Mesh | wet | 6500 IT | XF-1200-1S |

salt | 1.2 | 30/80Mesh | dried | 5000㎏ | XF-1500-1S |

Corn Starch | 0.6 | 40Mesh | dried | 1600㎏ | XF-1000-1S |

Traditional Chinese Medicine Powder | 0.8 | 80Mesh | dried | 550㎏ | XF-800-1S |

PVC resin | 1 | 10㎜/5㎜ | dried | 3000㎏ | XF-1200-2S |

Polyethylene powder | 0.45 | 48/100Mesh | dried | 100㎏ | XF-800-2S |

graphite | 1.2 | 16/40/80Mesh | dried | 1400㎏ | XF-1000-3S |

lead powder | 11.34 | 10/80Mesh | dried | 1000㎏ | XF-1000-2S |

emery | 4 | 60Mesh | dried | 300㎏ | XF-1000-1S |

Aluminum powder | 0.9/1.2 | 80/120Mesh | dried | 350㎏ | XF-800-2S |

Welding rod powder | 0.95 | 20/200Mesh | dried | 550㎏ | XF-1000-2S |

kaolinite | 0.4 | 100Mesh | dried | 200㎏ | XF-1000-1S |

mud | 1.1 | 250Mesh | wet | 3200㎏ | XF-1000-1S |

chemical fertilizer

chemical fertilizer Traditional Chinese Medicine Powder

Traditional Chinese Medicine Powder Traditional Chinese Medicine Granules

Traditional Chinese Medicine Granules Traditional Chinese Medicine Liquid

Traditional Chinese Medicine Liquid MessageWe provide you with customized Screening Solution

MessageWe provide you with customized Screening SolutionIf you don't know how to choose, please call us or leave a message online. We will be happy to serve you!

Rich Production Experience

Rich Production Experience

Thirty years of dedication have allowed us to accumulate extensive production and service experience, enabling us to solve various challenges in powder processing for our numerous clients.

Complete production line design

Complete production line design

We specialize in undertaking the design and production of fine powder processing production lines, offering a one-stop service from crushing, screening, conveying, feeding, mixing to packaging.

High-Quality After-Sales Service

High-Quality After-Sales Service

Our company has a well-established after-sales service management system. Customers facing product issues can receive immediate assistance 24/7 via our dedicated support hotline.

Renowned in over 100 countries and regions worldwide, our premium products and services have earned the trust of leading global brands and Fortune 500 enterprises.